MILEK ENGINEERING

WHAT WE DO

Milek prides itself on the ability to work with customers, to offer innovative, cost-effective, quality solutions and services that aim to maximise operational availability and enable efficient maintenance of the equipment throughout its lifecycle.

This philosophy manifests in a range of original equipment and proprietary products as well as engineering solutions, relating to electrical systems and support equipment, including but not limited to those outlined in the equipment, products and service pages linked below.

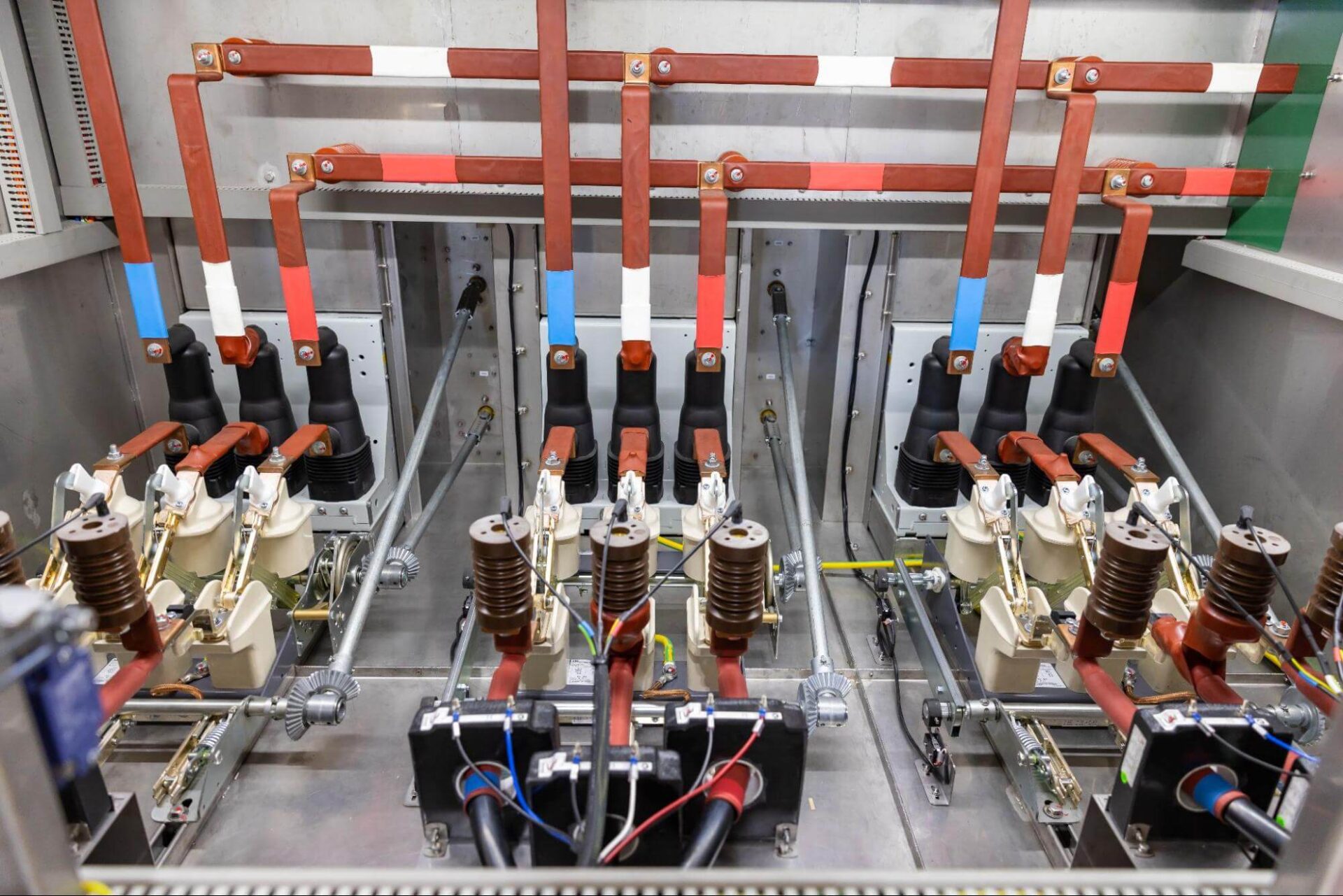

DESIGN

We have internal capabilities to design and build customised power and control systems to bring your OEM equipment to life.

-

Inventor 3D modelling of skids, substations, panels switchboards.

-

AutoCad Electrical for design of schematics.

-

Rockwell systems integrator for automation of your project.

-

FEA analysis for ARC fault containment.

By engaging with the end user in our equipment’s design phase, we can provide benefits to our customers throughout the product life.

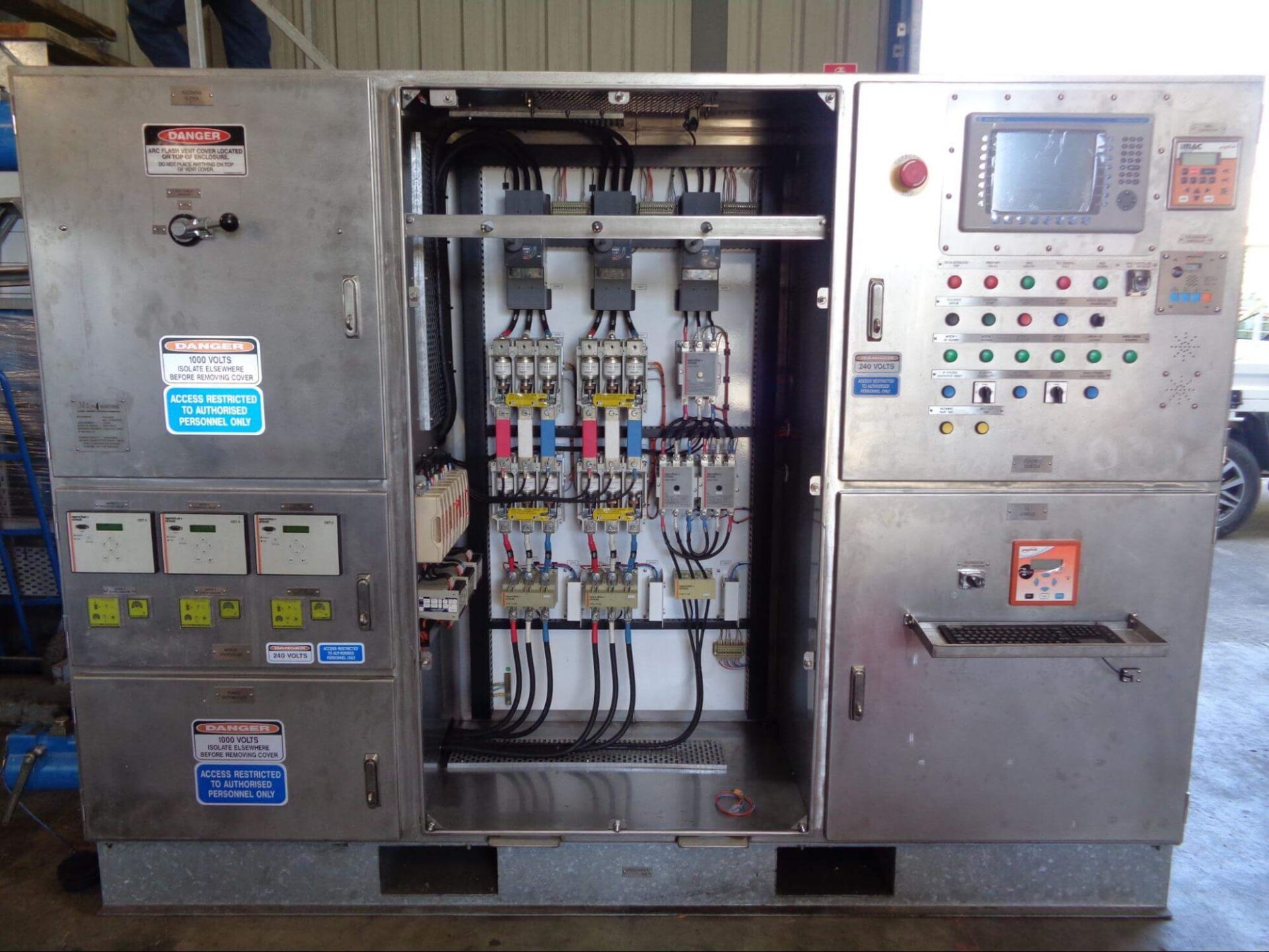

MANUFACTURING

Having worked in the industry for over 30 years, we have developed a good understanding of what’s important to our customers, considering legal compliance, ease of installation, reliable operation and simple maintainability guiding our design team. We can take your project from an idea, through the design and build phase, to onsite installation.

AUTOMATION

Milek has been providing Automation services since its commencement in 2014, as a Rockwell systems integrator and supporting other Vendor products. The services we offer start at the development and commissioning of individual OEM equipment through to development and support of site-wide PLC and SCADA systems.

- Manufacture of local and distributed automation Panels

- Program development and Testing

- Factory, and On-Site commissioning support

- Citect, Rockwell, and Clear SCADA supervisory Systems.

SERVICES & MAINTENANCE

Milek can support your operations both on and off site, with trained, supported staff in the following areas.

- All Electrical Design & Drafting

- PLC / SCADA program development and plant control optimisation

- On-site Technical, Commissioning and Project Management Support

- Electrical & Instrumentation installation and maintenance.

- Equipment Overhaul / Lifecycle Management

PRODUCTS

Adding to our capabilities, over the last 3 years we invested time and capital into developing the below Conveyor protection devices we believe are superior in construction, reliability and operation to other devices in the market, and are also proudly Australian designed and manufactured.

PLATEN CONTROL BOX

We pride ourselves on the ability to work with customers, to offer innovative, cost effective, quality solutions and services that aim to maximise operational availability and enable efficient maintenance of the equipment throughout its lifecycle.

This philosophy manifests in a range of original equipment and proprietary products including the Platen Control Box.

BELT WANDER

The Universal WANDER switch is utilised to provide Belt tracking detection as per AS4024.3611 table 1, which imposes mandatory requirements for belt tracking at various location on conveyor systems.

The Universal term refers to the ability for the switch to be easily changed from left hand to right hand activation.

The switch will activate when the roller arm is rotated in either direction.

BELT RIP

The Universal Belt Rip switch is utilised to provide Belt integrity detection as per AS4024.3611 for rips and tears in the conveyor belting.

The Universal term refers to the ability for 4 possible locations for the receiver, top, left, right and rear.

CALL US TODAY

INTERESTED? CALL US TODAY

Call us today to speak with one of our qualified team members to find the most efficient and innovative solution to your problem.

CONTACT US

SEND US A MESSAGE

"*" indicates required fields